Reykongbebe Quartz Cutting Machine For Sale

Quartz cutting machines enable precision shaping to craft intricate designs with impeccable accuracy and detail.

Quartz cutting machines offer versatile designs and efficient production, making them the ideal solution for numerous industrial applications.

Quartz cutting machines boast economic and environmental advantages that outshine other cutting tools on the market, including reduced waste production and cost efficiency.

Did you like this product? Add to favorites now and follow the product.

(+800) 1234 5678 90 Start Live Chat

描述

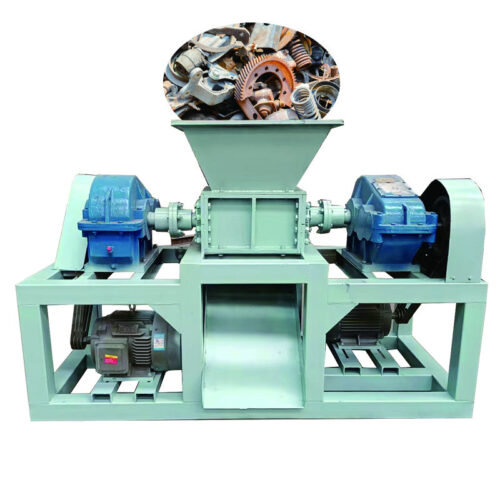

Quartz Cutting Machines: Quartz cutting machines are sophisticated equipment designed for precisely shaping and cutting quartz materials and equipped with cutting-edge technologies, such as diamond-tipped blades or abrasive waterjets, to carve intricate patterns or edges into raw quartz material. Such precision- and versatility-enhanced machines have proven integral in producing countertops, tiles, sculptures, and various industrial components containing this mineral compound.

Applications of Quartz Cutting Machines:

Quartz Countertops and Surfaces:

Cutting machines are integral in fabricating quartz countertops for kitchens and bathrooms, offering precise cuts that create seamless fits that add visual interest while providing seamless edge profiles for smooth results. Their ability to produce intricate designs adds further aesthetic value, making these surfaces popular in contemporary interior design schemes.

Architectural and Decorative Elements:

Quartz cutting machines craft decorative elements for wall panels, flooring tiles, and intricate sculptures in architecture and interior design. Their ability to execute precise cuts allows the creation of unique designs that enhance the visual appeal of spaces.

Electronics and Semiconductor Manufacturing:

The semiconductor industry relies heavily on cutting machines with quartz components used in electronic devices for precise shaping. These machines ensure precision when producing quartz wafers or other semiconductor materials to increase efficiency and improve the performance of electronic circuits.

Optic and Precision Instruments: Quartz’s exceptional optical properties make it the go-to material for making lenses, prisms, and precision instruments such as cameras. Cutting machines use quartz as their cutting material in shaping and refining these components for use in fields like astronomy, microscopy, and telecom.

Industrial Applications: Wonder cutting machines have many uses across various industries, from automotive and aerospace to dental and education. Their primary function is missing and shaping quartz components for machinery, ensuring durability and precision when necessary for critical industrial processes.

Advantages of Quartz Cutting Machines:

Superior Precision: These cutting machines boast unmatched precision for intricate cuts in quartz materials – this precision makes it essential in industries where accuracy is critical, such as electronics or optics.

Versatility in Design: Quartz cutting machines offer incredible versatility when designing products with various designs, edge profiles, and shapes for architectural or decorative uses. Their flexibility also enables the production of customized quartz products specifically tailored for these purposes.

Efficiency in Production:

Quartz cutting machines facilitate efficient production processes by quickly and precisely shaping quartz materials – essential in meeting high-demand requirements in industries spanning construction to electronics production.

Material Waste Reduction:

Quartz cutting machines use their precise cutting precision to minimize material waste by optimizing the use of raw quartz, helping ensure cost-effectiveness while adhering to sustainability practices in material utilization. This contributes both financially and sustainably.

评价

目前还没有评价