Reykongbebe Bore Welding Machine For Sale

Bore welding machines provide precise internal welding services in tight spaces to provide accuracy and consistency of results.

Flexibility in bore sizes provides enhanced adaptability for these machines to accommodate various industries and applications.

Advanced features, like automated systems and in-process monitoring, boost efficiency by decreasing manual effort while guaranteeing top-grade welds.

Did you like this product? Add to favorites now and follow the product.

(+800) 1234 5678 90 Start Live Chat

描述

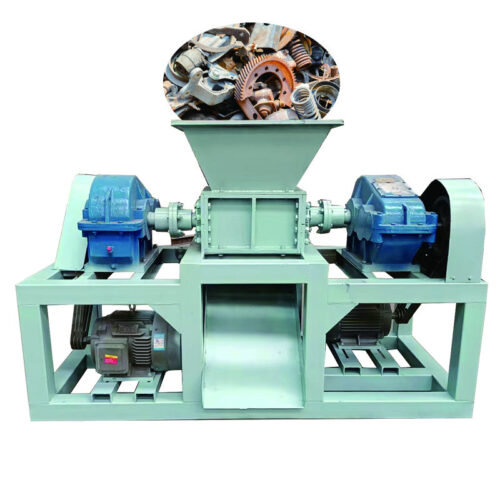

Bore welding machines Introduction.

Bore welding machines (sometimes referred to as internal bore welders) are precision tools designed for welding internal bores and pipes with ease, offering precise welding in tight spaces without costly replacement costs. Equipped with advanced welding heads and systems enabling accurate control welding within limited spaces confined areas – bore welding machines have proven especially valuable when it comes to repairing worn out components that would have required costly replacement otherwise.

Applications of Bore Welding Machines:

Manufacturing and Fabrication:

Bore welding machines play an essential part in the production and assembly of components with internal bores, including hydraulic cylinders, engine blocks and other intricate parts that rely on precision welding for optimal performance and durability. These machines ensure precision welding for optimal performance and long term usage.

Repair and Maintenance in Heavy Industries: Bore welding machines are increasingly being employed across many heavy industries such as mining, construction and oil and gas to restore worn or damaged bores in components like hydraulic cylinders to restore them for continued operational efficiency while simultaneously decreasing downtime.

Aerospace Component Refurbishment:

Bore welding machines are commonly employed within the aerospace industry to refurbish critical components like landing gear cylinders and hydraulic systems, meeting stringent aerospace standards while contributing towards increased safety and reliability within aviation.

Automotive Engine Block Repair: Bore welding machines have become an invaluable asset to automotive engine block repair in recent years, particularly for salvaging worn-or-damaged engine blocks and providing cost-efficient alternatives to complete engine replacement.

Shipyard and Maritime Repairs:

Bore welding machines have proven invaluable in shipyards for repairs to marine components like propeller shafts and hydraulic cylinders, where precision internal welding in tight spaces is crucial in protecting essential maritime equipment from becoming compromised over time.

Advancements in Bore Welding Machines:

Automated Welding Systems: Modern bore welding machines include automated welding systems to reduce manual operation reliance. This not only increases productivity and consistency in welding procedures but also contributes to higher-grade welding results.

Advances in bore welding technology now incorporate in-process monitoring and control features for real-time monitoring of welding parameters during welding process to enable adjustments during weld operation to reach desired weld quality with reduced postweld correction needs.

Adaptable Welding Heads:

Bore welding machines feature adaptable welding heads designed to accommodate different bore sizes and configurations for greater versatility across various industries. This feature extends their use.

Modern bore welding machines feature portable and compact designs to facilitate on-site repairs without the hassle of transporting large components for repairs. Such models make life simpler for industries in which transporting such repairs would otherwise be impractical, offering convenience to users when transporting repairs becomes impractical.

Integration of Advanced Materials: Wedge welding machines today can accommodate an increasingly wide variety of advanced welding materials, from high strength alloys and exotic metals, to meet the evolving requirements of industries requiring customized and durable welding solutions. This means bore welding machines have become even more adaptable when it comes to meeting industry-wide challenges requiring customized and long-term welding solutions.

Bore welding machines represent the pinnacle of precision welding technology, meeting the complex welding needs associated with internal bores in various industries ranging from manufacturing and aerospace through heavy industries and maritime. Bore welding machines contribute significantly to efficient repairs, extended component lifespan and overall operational reliability – in short providing innovative solutions to internal bore welding requirements that pose numerous challenges for businesses of various sorts. As innovations progress further bore welding machines will play an increasingly vital role in shaping welding practices as they provide innovative solutions to internal bore welding requirements that must be addressed.

评价

目前还没有评价