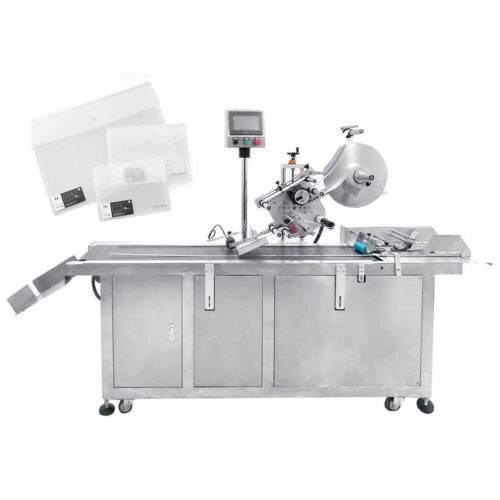

Reykongbebe Automatic Popsicle Packaging Machine For Sale

Automatic Popsicle Packaging Machines deliver precision, efficiency, and quick throughput – streamlining packaging processes seamlessly.

Customizable packaging configurations and customizable branding options elevate popsicle presentation.

Automatic Popsicle Packaging Machines in the frozen dessert industry have proven themselves effective with cost-efficient operations, consistent packaging quality, and the ability to accommodate various production scales. They represent considerable value.

Did you like this product? Add to favorites now and follow the product.

(+800) 1234 5678 90 Start Live Chat

描述

Automatic Popsicle Packaging Machine Introduction:

Frozen treats have experienced an extraordinary transformation with the introduction of Automatic Popsicle Packaging Machines, heralding an unprecedented packaging innovation. Automatic Popsicle Packaging Machines represent the pinnacle of automation technology geared to efficiently and precisely package popsicles – featuring automated feeding, sealing, and labeling mechanisms with one goal being consistency, hygiene, and speed during their production run-up process.

Applications of Automatic Popsicle Packaging Machines:

Automatic Popsicle Packaging Machines Are A Popular Option In High-Volume Production Facilities: Popsicle packaging machines find extensive use in facilities with high demand for packaged popsicles, such as high-volume frozen treat manufacturers. When integrated seamlessly into production lines, these machines ensure an uninterrupted packaging process that meets large-scale manufacturers’ demands for packaging services.

Versatile Popsicle Presentation: These machines provide versatility in popsicle presentation by accommodating various shapes, sizes, and configurations of popsicles. From single-flavor treats to complex, multilayered creations, automatic packaging machines meet consumer tastes across a spectrum.

Customizable Branding and Labeling:

Automatic Popsicle Packaging Machines provide customizable branding and labeling capabilities, adding visual appeal and increasing marketing and consumer engagement efforts. Manufacturers can add branding elements, nutritional facts, and eye-catching graphics that boost visuals on packaged popsicles for enhanced marketing efforts and consumer engagement.

Retail-Ready Packaging: Automatic packaging machines produce retail-ready packaging that makes popsicles instantly shelf-ready, offering retailers attractive frozen treats that engage their target consumers to drive up sales and brand visibility. This is essential for reaching new markets while increasing revenues overall.

Hygienic and Sealed Packaging: Automatic Popsicle Packaging Machines prioritize hygiene and product integrity through hermetically sealed packaging that preserves freshness and quality – protecting consumer wellness! Hermetic seal packaging not only keeps quality but also meets food safety regulations. It is an integral component of consumer well-being!

Small Batch Production Efficiency: These machines can quickly adapt to smaller production settings without losing efficiency, making them ideal for boutique popsicle makers who wish to automate packaging without compromising the speed or quality of packaging processes.

Advantages of Automatic Popsicle Packaging Machines:

Automation Features Enhance Production Efficiency:

Automation features of these machines can significantly boost production efficiency by decreasing manual labor requirements and increasing throughput – this feature is precious during high-demand periods or sudden market trends.

Automatic Popsicle Packaging Machines Provide Consistent and Precise Packaging:

Automatic Popsicle Packaging Machines ensure consistent and precise packaging by eliminating variations in seal quality or presentation of popsicles, further contributing to brand integrity and consumer trust. The reliability of these machines contributes to brand continuity.

Cost-Effective Operations:

Automatic packaging machines offer cost-effective operations by optimizing resources, minimizing wastage, and eliminating extensive manual labor demands – creating more streamlined processes and increasing profitability among popsicle producers.

Adaptability Enhancing Product Diversity:

These machines’ adaptability to various popsicle types, sizes, and configurations contributes significantly to product diversity. Manufacturers can quickly introduce new flavors, designs, or packaging formats without significant adjustments to their production line.

Integration With Smart Packaging Technologies:

Modern automatic popsicle packaging machines can seamlessly integrate with intelligent packaging technologies, including features like QR codes for traceability and temperature indicators for quality assurance – features that help modern popsicle packaging machines adapt to the ever-evolving landscape of intelligent and connected packaging.

Conclusion:

Automatic Popsicle Packaging Machines have emerged as one of the industry’s key innovations, providing sophisticated solutions for efficiency, consistency, and presentation challenges in high-volume production facilities and boutique popsicle makers. From extensive production facilities to boutique makers – these machines meet various customer demands across multiple locations.

评价

目前还没有评价